What number of teeth is best to use when cutting timber?

The suitability of any sawblade to its purpose is determined largely by a single factor, the type of cut you intend to make - rip, rip/cross (combination) or dedicated crosscut or fine cut.

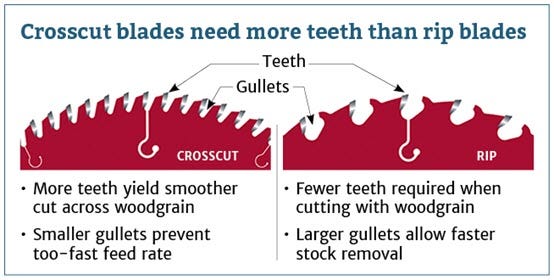

The number of teeth varies depending on whatever they are meant to remove material smoothly or quickly. A rule of thumb is simply the lower the tooth number, the faster the cut and the higher the tooth number, the finer the cut.

Ripping Saw Blades

Ripping saw blades are designed for efficient and smooth ripping. For optimum rip cutting it is best to select a saw with a low tooth number. The low tooth count and large gullets combine to make this blade fast and aggressive while making the cut absolutely flat and precise.

Ripping wood produces large chips because of the long wood fibres in the long grain. This necessitates large gullets to give room for the large chips to be removed safely, cleanly and without obstruction. Without these large gullets there is a danger that the blade could overheat and become dangerous. Rip saw blades must be accompanied by a matching riving knife to prevent the cut portion of the timber from closing on the back edge of the spinning blade, thereby propelling it straight back at the operator – a phenomenon called ‘kick back’. Therefore a riving knife is mandated by OSH on all circular saws to prevent injuries and fatalities.

Compared with the rip cut, the cross grain cut creates small chips. With small chips, achieving cleaner cuts is done by increasing the tooth count. Because of the short grain, the wood being removed has much smaller chip size and does not need large gullets to escape. Please note that if your sawblade is producing dust, it is blunt. No sawblade should produce dust!

Crosscut Rip Saw Blades

Crosscut Rip saw blades, commonly known as combination blades, have more teeth and have an alternate bevel tooth grind. These saws perform both the ripping and cross-cutting tasks well on thinner timber, say up to 25mm thick. Ripping thicker than this, the gullets tend to clog with the amount of long chip generated by rip cutting. The alternate bevel tooth gives a chisel effect enabling good, clean crosscuts to be made right up to the max diameter of the sawblade

A dedicated rip blade and a dedicated crosscut blade will enable you to achieve a much cleaner cut than a combination. Let's be clear though, when using a high-quality combination blade, you still achieve very clean cuts.

Fine Crosscut Saw Blades

Dedicated crosscut saw blades typically have more teeth than crosscut rip types. These teeth also have an alternate tooth bevel. An alternative teeth bevel provides a cleaner cut. Additionally, the gullets on the crosscut blade tend to be shallower, giving the blade a less aggressive stance. These blades work well when a clean crosscut is needed in thicker materials.

Fine Finishing Saw Blades

Dedicated fine finishing blades are for the precision cabinetmaker and furniture maker with a high precision table saw or dimension saw. They have more teeth than the fine crosscut blades and different tooth geometry to optimise cut quality in fine wood, plywood and laminated board products. They create a clean, fine cut in all timbers but tend to be slower cutting in thicker materials.

Skip to content

Skip to content